In my continued look at disruptive scenarios, the focus shifts to 3D printing. Growth in this key innovation is expected to accelerate to $10.8 billion by 2021 according to Goldman Sachs. The economic implications are significant: Research by McKinsey Global Institute suggests a possible impact of $550 billion per year by 2025. Some believe that 3D printing will play a crucial role in launching a third industrial revolution at a personalized level.

Advances have brought 3D Printing to a tipping point. These advances allow for greater precision and finer resolution in the building of larger components at higher speeds and lower costs. As a result, the range of parts that can be economically manufactured using 3D printing will broaden dramatically. This is not science fiction – it is already having an effect on the economy. Traditional uses focused on creating prototypes, but GE and others have already produced critical parts and final products. According to the Wohlers Report 2013, 28 percent of the global 3D printing market in 2012 was tied to the production of parts for final products rather than prototypes. By 2025, 3D printing could account for 10% of all consumer products. That shift could have profound implications for the economy and public policy.

One of those profound implications is a potential maker economy where in do-it-yourself fashion; individuals design and produce their own goods. Traditional companies could be disrupted by communities that crowd-fund, design and produce goods, then sell those goods through their own global marketplaces. With this as a backdrop, let’s look at the benefits, obstacles, disruptive scenarios, and re-imagined responses associated with 3D Printing.

Benefits

There are many potential benefits that 3D printing can deliver across several different categories. One significant advantage of additive manufacturing is the elimination of waste that accrues in subtractive manufacturing. 3-D printers build an object by layering plastic or other material guided by a design file. The waste of traditional manufacturing – where up to 90 percent of raw materials can be discarded – is eliminated. In the area of productivity, the potential for gains is high, as seen in the following examples:

- Reducing development time and simplifying production runs

- Reducing large inventories, costs, and taxes

- Reducing transport as production and assembly can be local

- Fewer unsold products as companies make them as needed

- Shorter supply chains

- Reducing product-launch risk and time to market

- Eliminating excess production

The benefits don’t end there, as 3D printing makes it possible to create complex shapes and structures that were not feasible before. It can create objects with geometries and internal complexities that traditional factory machines can’t match. Unique and complex goods that never existed before will be printed, as inventors will be freed to imagine products never attempted before, unburdened by the limitations of traditional manufacturing. With this new found design freedom, new products, and new markets are possible, as well as the expansion of personalized products or services.

Benefits also accrue to society in areas like providing prosthetic limbs to those in developing countries. Examples already exist in the 3D printing of prosthetics to disabled Ugandans, and a war amputee in South Sudan who had a prosthetic arm created for $100. In Haiti, projects to print life-saving medical instruments are underway to meet the needs of doctors struggling to serve a growing population.

Obstacles and challenges

Like every building block, 3D printing will have its challenges. There are sure to be licensing issues as individuals compete with traditional companies. Free designs are bound to cause issues with intellectual property, and reverse-engineering of objects may drive piracy and lead to replication. In addition, there are questions about inefficiencies, as research suggests 3D printers may actually be less environmentally friendly. If everyone were to print their own products, it could drive waste and resource scarcity.

Can we print guns and make it easy to get around gun laws? What about child-safety or the impact on the economy? Do traditional companies go out of business and drive massive unemployment? I explored this in my post on Next Generation Automation. As more tasks are automated; a re-skilling of the workforce is required. Some analysts believe that 3-D printing will eventually create many jobs, but those jobs won’t resemble what we have today. We may be heading towards a time where technologies like 3D printing obviate the need for employment as we currently know it – a topic handled brilliantly in a new book titled The Second Machine Age. From a legal standpoint, issues range from intellectual property to consumer protection and even weapon possession. Can I print dangerous or unregulated drugs, or objects that pose national security risks?

Disruptive scenarios

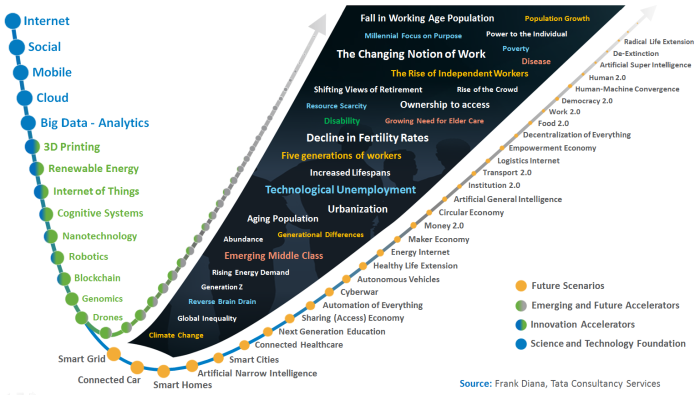

The objective of this current Blog series is to understand disruptive scenarios enabled by innovation. Building blocks like 3D Printing are disruptive on their own, but can combine with other innovations to create larger disruptive scenarios. In this case, 3D printing will disrupt the obvious Industries and blind side many others. Much like other disruptive scenarios, it is hard to imagine an industrial category that is safe from its far reaching implications. In effect, all aspects of production become digitized and controlled by software. This blurring of physical and digital boundaries allows 3D printing to expand the reach of digital disruption and has profound societal implications that change the way we live. As it evolves, the cost of market entry for new competitors drops, and individuals increasingly become inventors with an ability to manufacture.

According to a study by the Michigan Technological University, the price of 3D printers is dropping to a point where the average person can own one. This drives a resurgence of a “maker” culture where individuals print objects in their home. These implications drive companies to shift the basis for competitive advantage away from high volume, low cost manufacturing, to areas like design and broader ecosystem participation. With this in mind, let’s look at disruptive scenarios driven by 3D Printing.

Transforming Industries

3D printing could transform industries in unexpected ways. For example, the electronics industry is impacted by a new found ability to print objects that require complex geometric features. Custom jewelry can be created using 3D printers without the need for large-scale, complex, and expensive machinery. When it comes to toys, 3D printers will change the way children play, as they download design files for toys that they customize and produce in their homes.

In the Automotive industry, vehicle parts and entire cars will be 3D printed. Bentley has already demonstrated the feasibility of using 3D printing for small, complex parts. 3D printers are used to create new types of modern art, enable innovation in education, and revolutionize mass manufacturing.

Changing ecosystem dynamics

3D printing has a broad ecosystem impact. For example, as goods are printed at the local level, the need for transportation, warehousing, or other value chain services diminishes. Supply chain partners in transportation will see fewer packages, containers, and less profit, while taxes levied at each step of the transaction are lost. Additionally, the affect on global shipping impacts the need for oil.

The localized production enabled by 3D printing will affect China’s current large-scale manufacturing industry. If complex goods can be printed rather than assembled – there’s a corresponding reduction in the need for manual labor from emerging markets. These labor implications could tip the balance toward production closer to end customers, and some off-shore manufacturing is already returning to the U.S. Alternatively, companies could find that the fully digital nature of 3-D printing makes it possible to produce complex parts in remote countries at lower costs.

Further ecosystem disruption is likely, when customized manufactured products are available as needed. Printing medicines at home that are personalized to your own specific genetic pattern impacts a number of ecosystem participants: local pharmacies, the global pharmaceutical industry, warehouses, labs, label manufacturers, post offices, couriers, tax departments, insurance companies, and governments.

The changing role of the consumer

Consumer shopping activity will eventually shift to buying and downloading designs online and printing the purchased item to their exact specifications at home or a local printer. Individuals will print replacement parts for household items right at home, rather than ordering them and waiting for them to be shipped. Some consumers could eventually shift from buyer to producer (Prosumer) and design products in the comfort of their own home. This phenomenon further shifts power to the individual – a trend that has been years in the making.

Structural impact

3D printing takes the personalization discussion to the next level, as it disrupts mass standardization and drives changes to business models and commercial laws. As it brings about new product development cycles, more companies will focus on customer-centered design. We can see how each of the building blocks (Mobile, Social, 3D printing, etc.) reinforce the structural change that we have witnessed over the last several years. Customer centricity and personalization may seem like the buzzwords of this current era – but they are structural.

Other structural implications include:

- Possibility of longer product life spans – replacing the worn parts of products when needed will drive an expectation to keep products longer. Planned obsolescence in product design could itself become obsolete, forcing a rethinking of innovation and growth strategies. This could lead to a product upgrade design model that is similar to the way we upgrade software today

- Crowd-sourcing replaces R&D activities – 3-D printing is another innovation that enables the crowd-sourcing of ideas and affects how companies will think about R&D in the future. Rapid prototyping with customers enables a rapid innovation cycle

- Differentiation via design – outsourcing the context (traditional manufacturing) helped companies like Nike grow a core design competence. As 3-D printing reduces the cost and complexity of production, companies are forced to differentiate their products in other ways, like creating personalized designs. The combination of mass customization and new design possibilities could prove very disruptive to traditional players

- Consumer expectations – existing drivers have already altered the expectation of consumers (e.g. consumerization). 3D printing exacerbates this, as consumers will expect more customization in the products they consume. While this drives more complexity, it also allows for greater value creation, customer loyalty, and profits

- Consumer needs – 3D printing enables the creation of products that were not possible before. This complicates an already difficult task of keeping pace with evolving consumer needs, and requires emergent capabilities to keep pace

- Government revenue – sales tax and employee tax are at risk as fewer citizens pay sales taxes, employment is impacted, and traditional tax paying companies collapse

- Aftermarket supply chains – a key challenge is managing inventories of spare parts for older, legacy products. The ability to manufacture replacement parts on demand using 3-D printers could transform the economics of aftermarket service and the structure of industries

Re-Imagined Response

There are two sides to this exercise: disruptive scenario analysis, and re-imagined response. I use the word re-imagined because increasingly, traditional responses fall short. So given these possible disruptive scenarios, what are some likely ecosystem responses? Some traditional companies are already experimenting. For instance, some people may indeed use 3D printers from the home, but Staples is betting that they’ll use a print shop to produce designs they have either purchased or created themselves. In Europe, Staples is providing a service where customers can upload design files to a website, and have the product printed at their local Staples. New market entrants are emerging rapidly, buoyed by the technology’s ability to democratize the way start-ups compete with bigger players.

Another likely response is moving production closer to the customer – enabled by 3D printing as well as advanced Robotics. Additionally, as personalization for the masses becomes a reality, companies will benefit by facilitating access to personalized, just-in-time production. Driven by the combinatorial power of 3D printing, the Internet of Things (IoT), Big Data, and artificial intelligence, companies will pursue software-driven business models in which every aspect of a physical product — from creation to delivery — is digitally controlled. This blurring of the boundaries between digital and physical worlds will factor into many re-imagined responses.

NASA will respond by installing 3D printers on the international space station so astronauts can print replacement parts as needed, or dine on printed Pizza. Instead of layering plastic or metal, NASA’s “3D Printed Food System for Long Duration Space Missions” will layer starches, proteins, and fats. Small-scale manufacturers will respond with customized runs-of-one, and retail businesses will create goods in-house or indirectly through business relationships.

Individuals will exploit 3D printing with responses ranging from patenting their designs, to monetizing a collection of materials for re-use as part of 3D printing processes and a broader Circular Economy. Scrap plastic may become a valuable resource, and refining plastic for re-use as a raw material may become a growth industry. Salvaging metals or other post-manufactured materials or components may become as useful for individuals or small businesses as it is for large companies today.

Retail companies may respond by providing customized customer service departments to help fix, or update products in real time. This service focused, software inspired business model could therefore become the norm as 3D printing spreads. Governments must re-imagine how they help train the workforce, build curriculums, and support research. The White House took an important step last year, when it created the National Additive Manufacturing Innovation Institute, a public-private partnership dedicated to advancing 3-D printing.

There are countless other responses waiting for visionary leaders to pursue – but it starts with understanding the need to assess disruptive scenarios, experiment with a fail fast mindset, evaluate, and respond. It may seem like these science fiction scenarios are way off in the future – but evidence is mounting that this transformative period will happen on a time table unlike any we’ve seen before.

[…] In my continued look at disruptive scenarios, the focus shifts to 3D printing. Growth in this key innovation is expected to accelerate to $10.8 billion by 2021 according to Goldman Sachs. The econo… […]

LikeLike

[…] by the-view [link] […]

LikeLike

Frank – a nice article. One major disruption could be on the cards as items are scanned and then the models are 3D printed. There are several scenarios and none of them look particularly good for the original rights holder. Patents and copyright differ too. It will be a nightmare for an original article designer/manufacturer to prove infringement. Some legal action may succeed against those who scan and then sell but it is difficult to see how company x will sue Mr Bloggs who made a widget in his house after scanning his neighbours’s real one. The digital file is not even trackable unlike say a website site offering out designs.

LikeLike

[…] by FrankDiana [link] […]

LikeLike

[…] In my continued look at disruptive scenarios, the focus shifts to 3D printing. Growth in this key innovation is expected to accelerate to $10.8 billion by 2021 according to Goldman Sachs. The econo… […]

LikeLike

Hightlight Of My Day

LikeLike

[…] likely to transform logistics. Localizing production via innovations like vertical farming and additive manufacturing are examples of other transformative […]

LikeLike